CONDENSATE SYSTEM MANAGEMENT

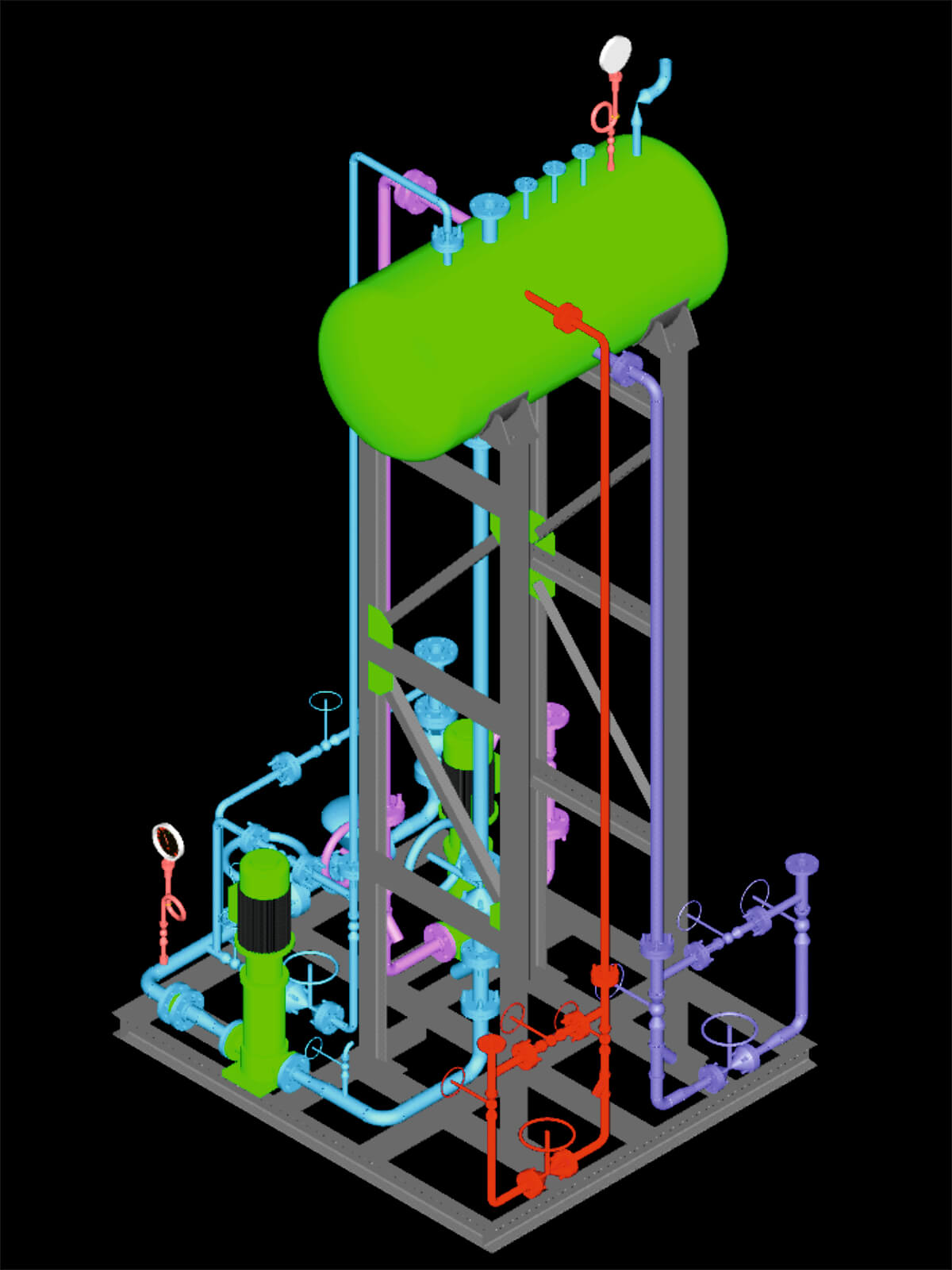

High Pressure Condensate Recovery System (HPCRS)

The HPCRS is a specialized steam condensate recovery system designed for industrial plants with condensate recovery exceeding 80%. It returns condensate directly to the boiler shell, improving energy efficiency and eliminating the need for a feedwater tank.

Appears under:

- Steam Distribution Pre-Fabricated Modules

- Condensate System Management

Key Features of HPCRS

- Elimination of vent steam loss

- Full recovery of condensate and flash steam to the boiler

- Microprocessor-based controller for system operation

- Flash steam prevention to maintain pressure and temperature

- Optimized steam generation with reduced fuel consumption

How HPCRS Works

HPCRS prevents condensate flashing, maintaining heat and pressure. This advanced system delivers fuel savings of 10% to 20% compared to traditional condensate recovery systems and includes specialized components like centrifugal pumps, control valves, pressurized tanks, and PLC-based controllers.

Benefits of HPCRS

- 100% recovery of condensate heat and water

- Zero condensate flashing

- Lower blowdown and water treatment costs

- Stable steam pressure and system reliability

- Substantial water and fuel savings

Industries Using HPCRS

- Rice Mills

- Rubber Vulcanizing

- Tyre Manufacturing & Retreading

- Corrugated Box Manufacturing

- Tea Industry

- Fish Feed Mills

- Paper Industry

- Rubber Belt Manufacturing