Industrial Manufacturing by Konark Global

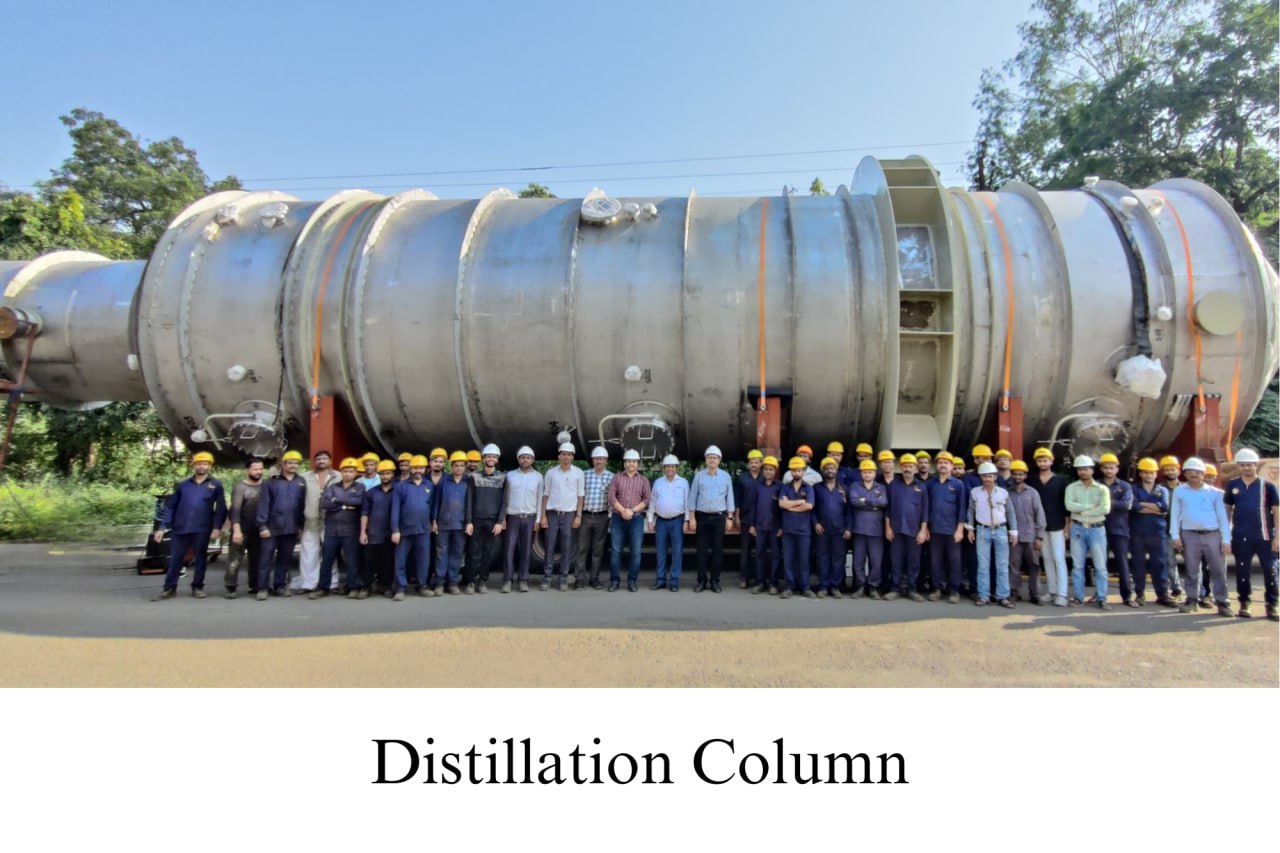

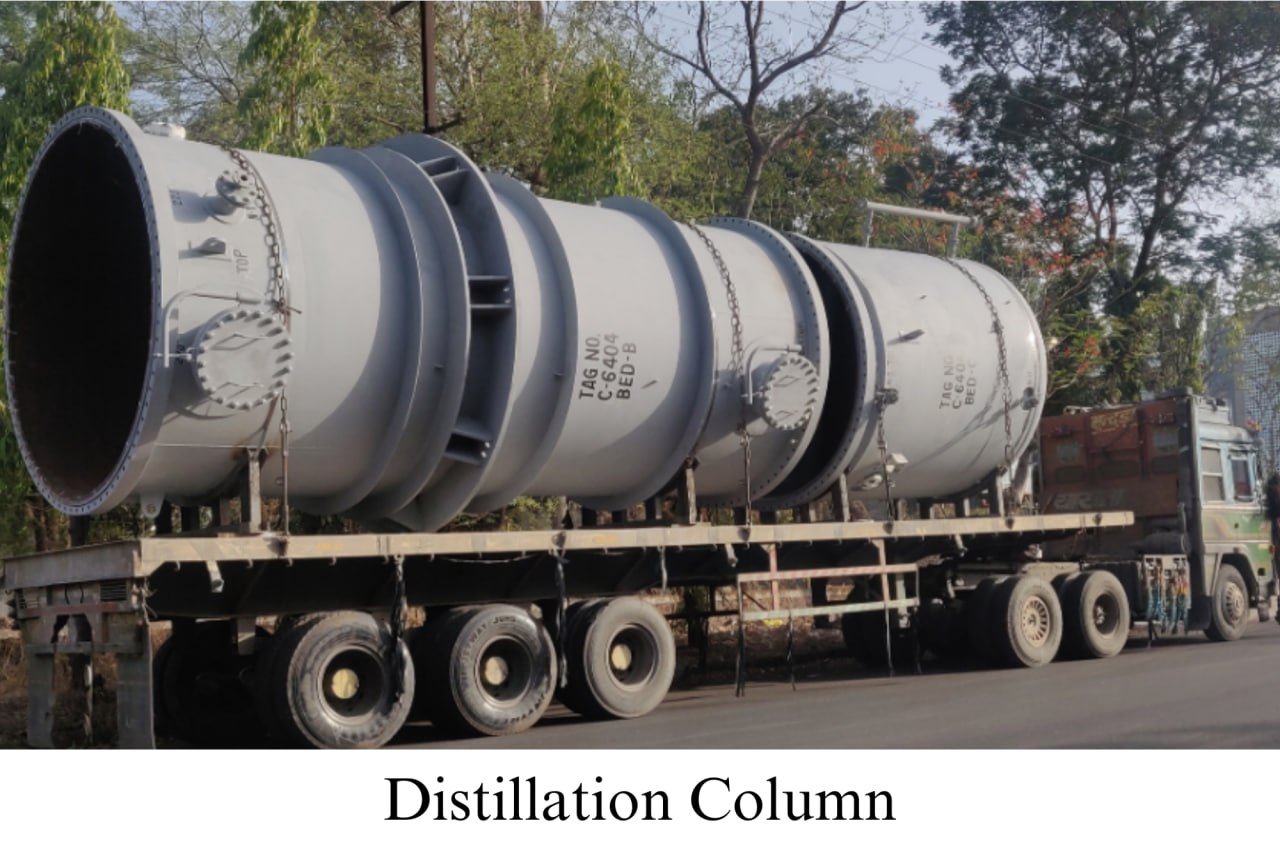

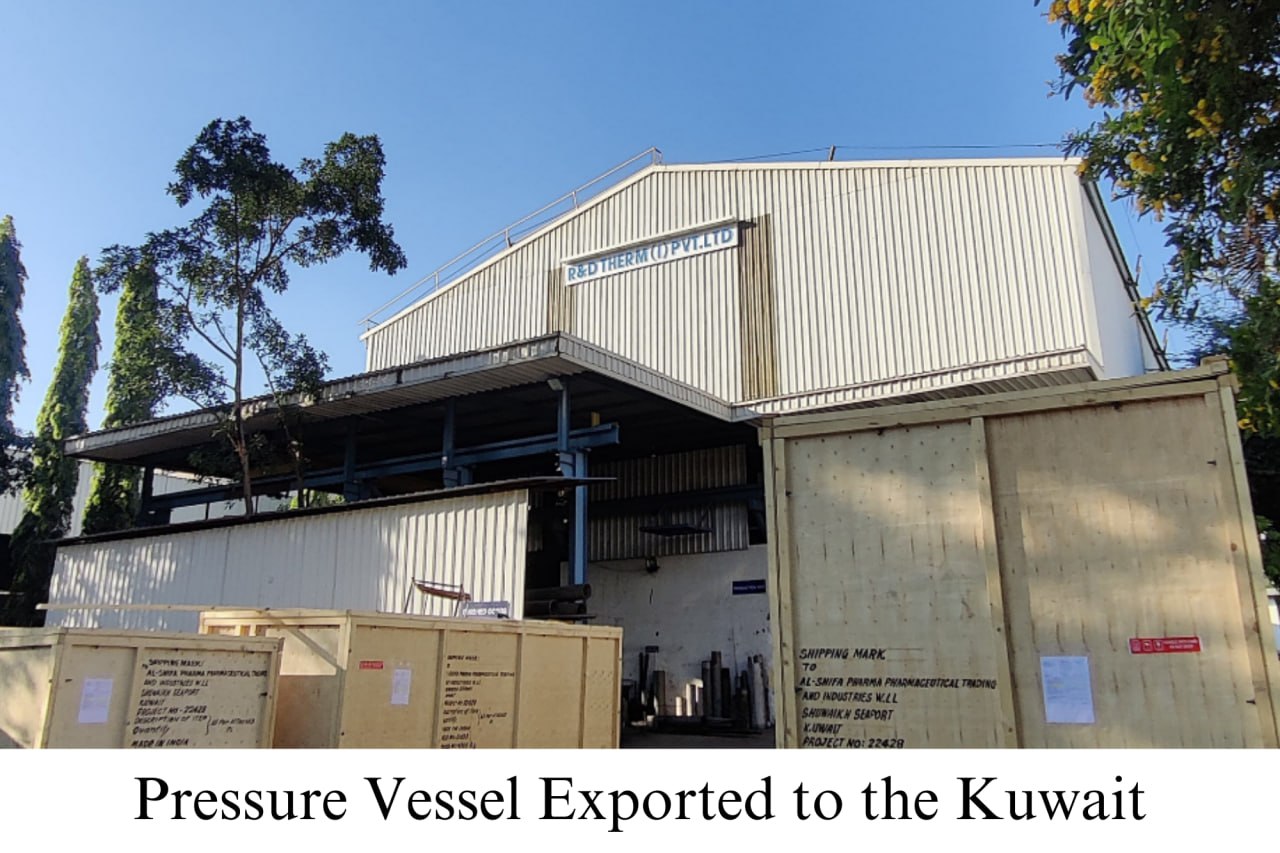

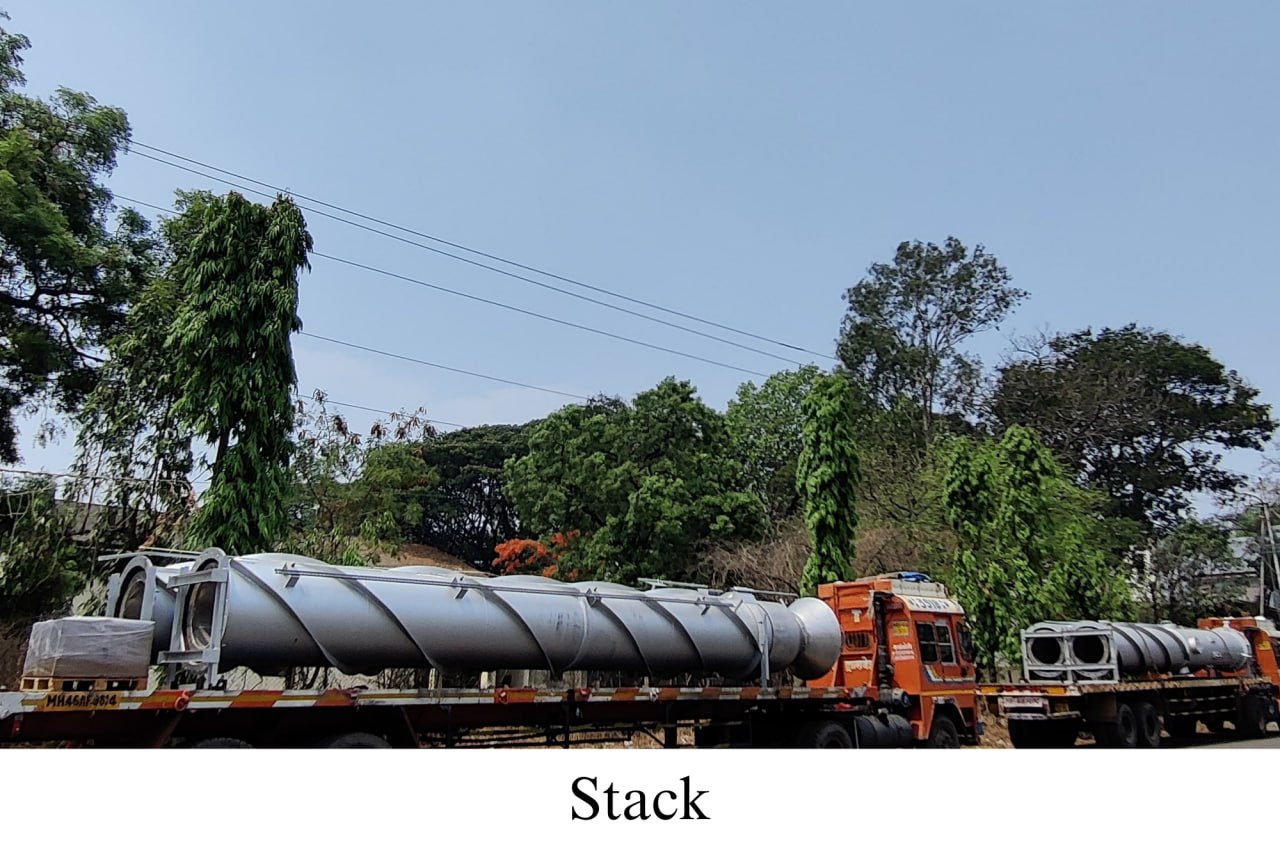

R&D Therm India Pvt Ltd (RDT) is a leading manufacturer in Nashik, specializing in industrial manufacturing of distillation columns, heat exchangers, pressure vessels, reactors, tanks, and chimneys. We use materials like SS 304, SS 316, Hastelloy, Titanium, Carbon Steel SA 515/516, and Mild Steel IS 2062 to deliver high-quality solutions.

R&D Therm India Pvt Ltd, the flagship of Konark Global, is located in Nashik, Maharashtra. Established in 1996, we combine technical expertise with innovative automation to deliver process equipment manufacturing and sustainable industrial solutions.

Why Choose R&D Therm?

Our sustainable performance is driven by:

- Strict adherence to manufacturing codes for pressure vessels and heat exchangers

- Compliance with quality standards, including ASME U Stamp and IBR approval

- Timely delivery of distillation columns and other equipment

- Continuous process improvements for enhanced productivity

- Teamwork focused on customer satisfaction

- Repeat business from satisfied clients

State-of-the-Art Manufacturing Facility

Located in Nashik’s Satpur Industrial Area, just 180 km from Mumbai, our state-of-the-art manufacturing facility spans 1 acre with a 40,000 sq. ft. shop and 13-meter shed height. Equipped with automated machines, we ensure fast delivery and top-quality process equipment manufacturing.

We work with leading consultants and Third Party Inspectors (TPI) like Lloyd's, TUV, Bureau Veritas, Chempro, Tata Consulting Engineers Ltd, Sulzer, Udhe India, EIL, Baxcounsel, TOYO Engineering Ltd., and Shiva Engineering.

As a proud ASME U Stamp certified and IBR approved manufacturer, we are expanding globally to deliver industrial manufacturing in Nashik and beyond.

Konark Global is committed to being your first choice for distillation columns India, heat exchangers manufacturer, and turnkey projects.

Get a Quote Today

Our Manufacturing Capabilities

| Distillation Column | Max Diameter: 2700 mm Max Length: 33 Meters |

| Heat Exchangers | Max Surface Area: 323 m² Max Pressure: 50 Bar |

| Pressure Vessels | Max Capacity: 35 KL Max Pressure: 50 Bar |

| Reactor | Max Weight: 9 Tons |

| Air Receiver & Surge Tanks | Max Capacity: 11 m³ Industry: OEM, Compressor Distributors, EPC Projects |