CONDENSATE SYSTEM MANAGEMENT

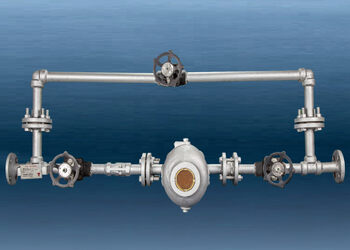

Float Trap Module – High Pressure Condensate Recovery System (HPCRS)

The Float Trap Module is a crucial component of the High Pressure Condensate Recovery System (HPCRS). Designed for plants where condensate recovery exceeds 80%, this system efficiently returns condensate directly to the boiler shell, bypassing the need for a boiler feed water tank. This leads to improved energy efficiency and better system performance.

Key Features of the Float Trap Module

- Efficient Process Condensate Drainage: Ideal for use in process condensate drain systems, maximizing energy recovery and reducing wastage.

- Flexible Installation: The module can be installed in any orientation, offering versatility to suit various system layouts.

- Enhanced Equipment Lifespan: Reduces scaling, which extends the life of boiler tubes and pressure vessels, ensuring long-term safety and efficiency.

- Easy Operation and Maintenance: Simple to operate and maintain, ensuring minimal downtime and lower operational costs.

- Consistent Monitoring: The inbuilt sight glass allows continuous and accurate monitoring of condensate levels for optimized performance.

Industries That Benefit from the Float Trap Module

- Brewery

- Garment

- Solvent Extraction

- Rice

- Tea

- Hotels